CNotes™ – Mobile Operator Rounds / Walk-down

During an operator round, operators inspect and monitor the condition and performance of assets and equipment. These rounds are essential for ensuring safe, efficient operations, identifying potential issues, and maintaining overall plant integrity.

Operators physically inspect various areas of the facility, monitor equipment status, check instrumentation readings, and look for any deviations from normal conditions. Rounds are conducted at regular intervals, following predefined routes and checklists

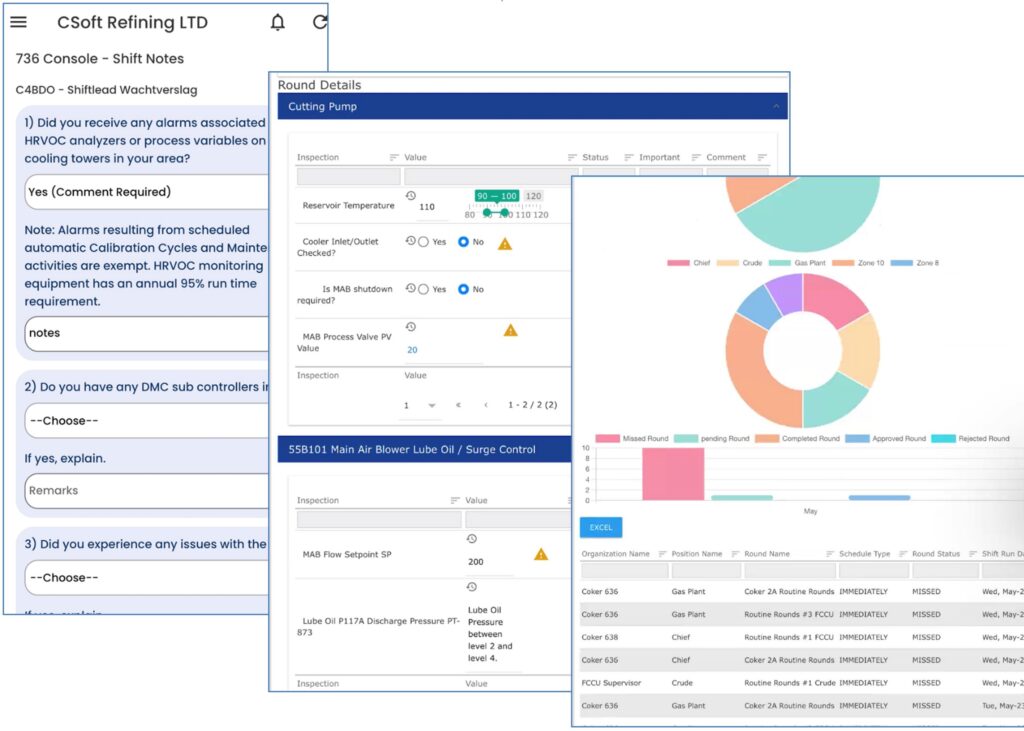

Mobile Operator Rounds application.

Key components of an operator round include:

Route Planning: Operators are assigned specific routes or areas to ensure full facility coverage.

Checklist Review:Before starting, operators review checklists or inspection forms to understand the items to be inspected and evaluation criteria.

Equipment Inspection: Operators check equipment for signs of wear, leaks, abnormal temperatures, or other potential issues.

Data Collection: Parameters such as temperature, pressure, and flow rates are recorded using handheld devices.

Observation Logging: Any issues are documented for further investigation or corrective action.

Communication and Reporting: After the round, findings are communicated to supervisors or relevant personnel, and formal reports are generated for record-keeping and follow-up.

Route Planning: Operators are assigned specific routes or areas to ensure full facility coverage.

Checklist Review:Before starting, operators review checklists or inspection forms to understand the items to be inspected and evaluation criteria.

Equipment Inspection: Operators check equipment for signs of wear, leaks, abnormal temperatures, or other potential issues.

Data Collection: Parameters such as temperature, pressure, and flow rates are recorded using handheld devices.

Observation Logging: Any issues are documented for further investigation or corrective action.

Communication and Reporting: After the round, findings are communicated to supervisors or relevant personnel, and formal reports are generated for record-keeping and follow-up.